Marc Houtermans

Manfred Zulauf

- Hazardous goods storage (bulk & packed)

- Filling of liquid and solid products

- Warehousing for liquid and solid goods

Bertschi Solutions specialises in worldwide product storage and handling using its own infrastructure.

At our hubs for dry bulk and liquid goods, we offer storage of chemical products in containers or in packed form (palletised drums and bags) in state-of-the-art facilities. Bertschi Solutions also provides a range of value-added services, including drum filling, container decanting or bag slitting.

The combined infrastructure for container storage and packed warehousing allows the customer to decide on short notice about the quantity and packaging of each delivery to the end-customer. The hubs serve as ideal distribution warehouses for supplying consignees in their respective regions. Thanks to the integration of Bertschi Solutions with the other business units, we are able to offer you integrated storage and transport from a single source.

Bertschi Solutions is experienced at planning and implementation of complex transport networks to reach very remote locations worldwide. Are your products needed in the Moroccan desert or in Siberia? Bertschi Solutions makes this possible for you in a safe and efficient manner.

Our infrastructure

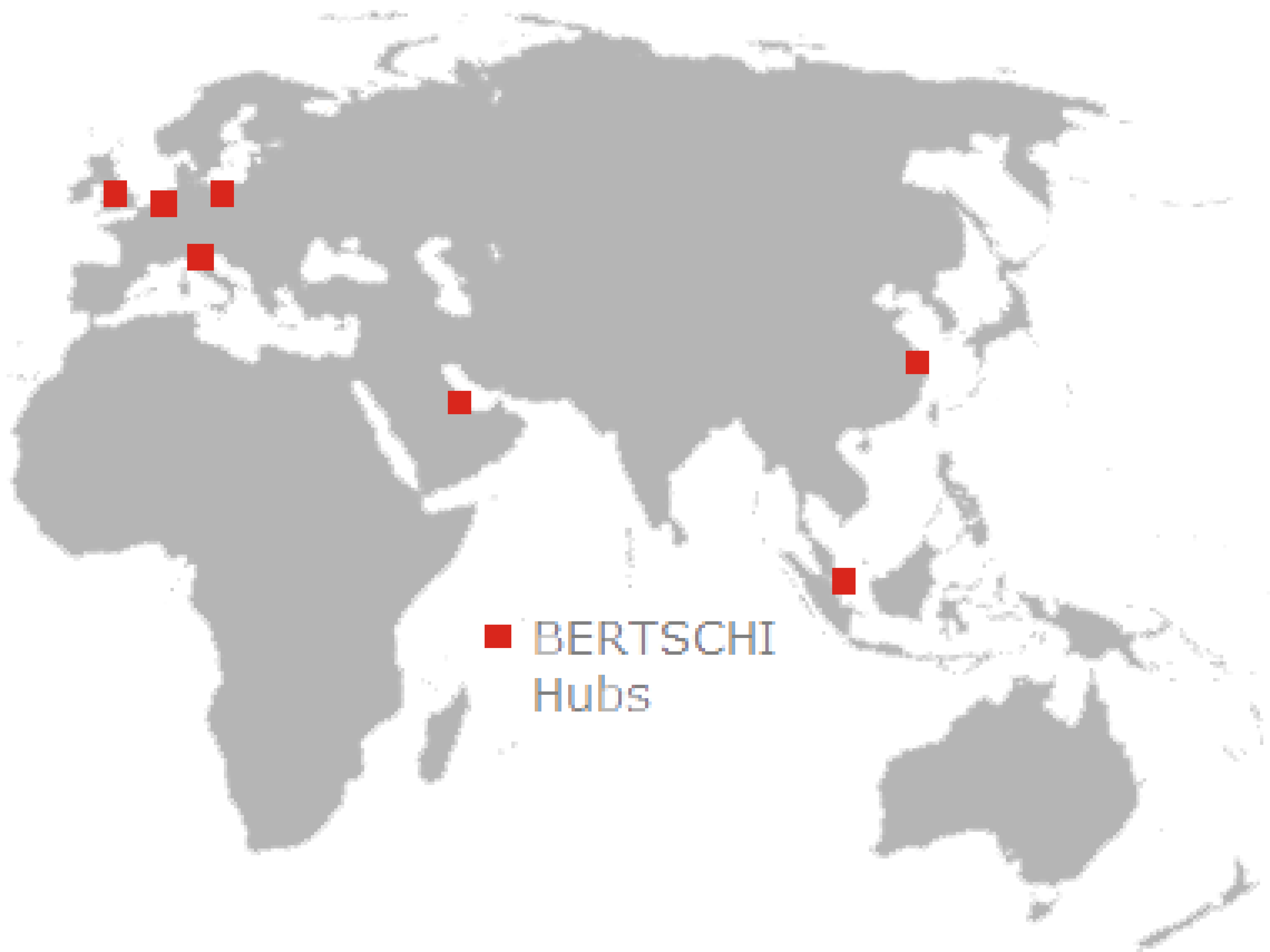

- Added-value plastics hubs located in Europe for overseas imports

- Middlesbrough (UK)

- Bologna (IT)

- Nola (IT)

- Wallhamn (SE)

- Antwerp (BE)

- Schwarzheide (DE)

- Liquids Hubs in Zhangjiagang (CN) and Singapore (SG)

- Jubail logistics platform (KSA)

- Various hazardous goods warehouses in Europe

- Rotterdam (NL)

- Schwarzheide (DE)

- Visp (CH)

- Tarragona (ES)

- Teesside, Middlesbrough (GB)

- Curtici-Arad (RO)

- Ploiesti (RO)

- Stara Zagora (BG)

Our locations

Our strengths

- Long-serving, experienced and motivated employees

- Added-value services, such as drumming or container decanting

- Modern warehousing infrastructure (e.g. high-rack pallet storage)

- Highest possible safety standards

- A range of concepts integrated with our Liquids, Dry Bulk and Global business units